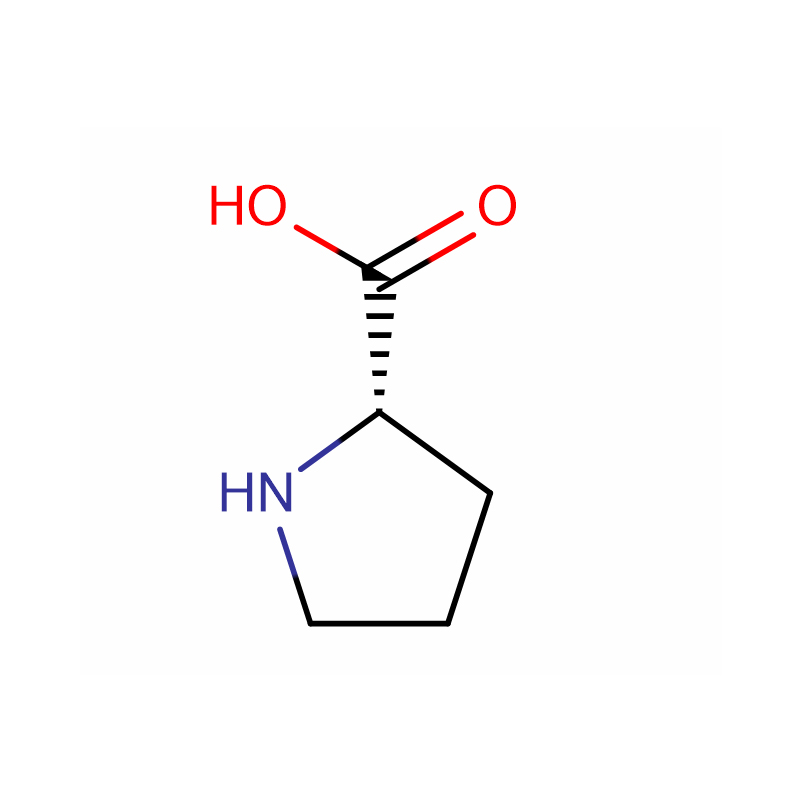

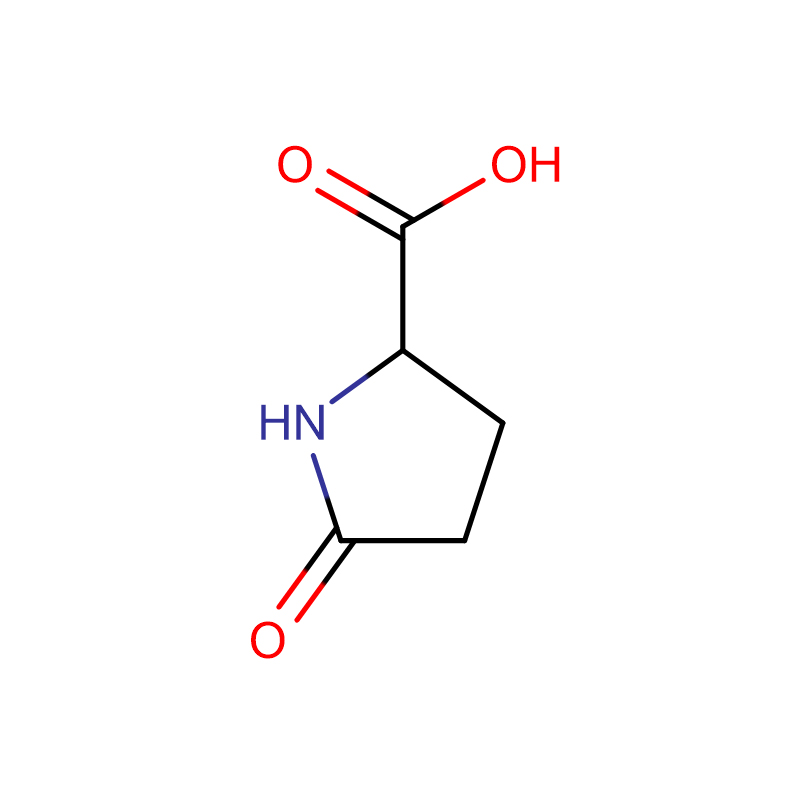

L-Proline Cas: 147-85-3 99% White powder

| Catalog Number | XD90293 |

| Product Name | L-Proline |

|

CAS |

147-85-3 |

|

Molecular Formula |

C5H9NO2 |

|

Molecular Weight |

115.13046 |

| Storage Details | Ambient |

|

Harmonized Tariff Code |

29339980 |

Product Specification

| Assay | 99%min |

| Appearance | White powder |

| Specific rotation | -84.5 to -86 |

| Heavy metals | <15ppm |

| AS | <1ppm |

| Ph | 5.9 - 6.9 |

| SO4 | <0.050% |

| Fe | <30ppm |

| Loss on Drying | <0.3% |

| Residue on Ignition | <0.10% |

| NH4 | <0.02% |

| Cl | <0.050% |

| State of Solution | >98% |

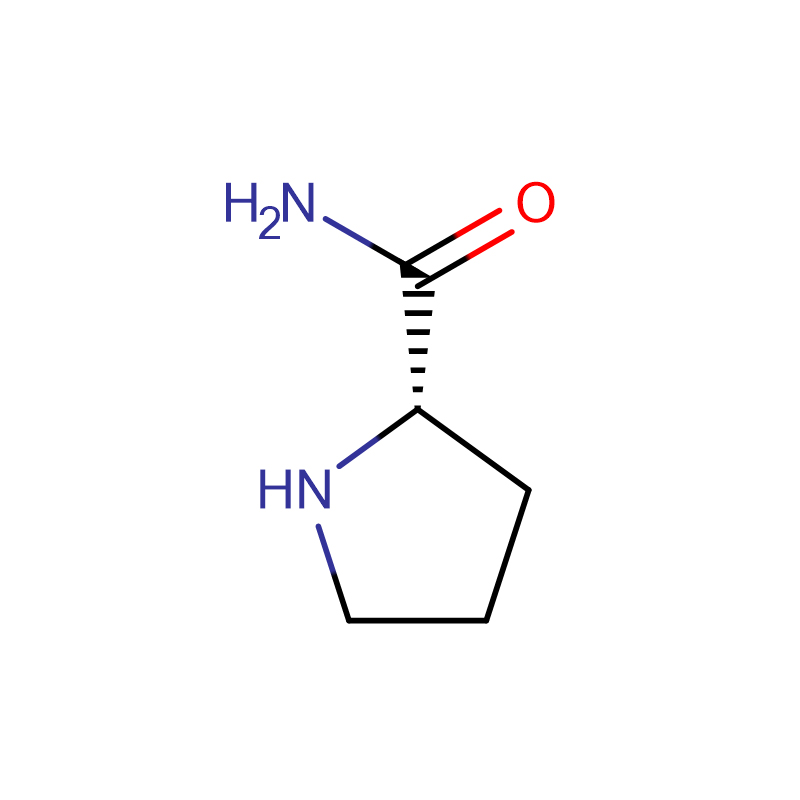

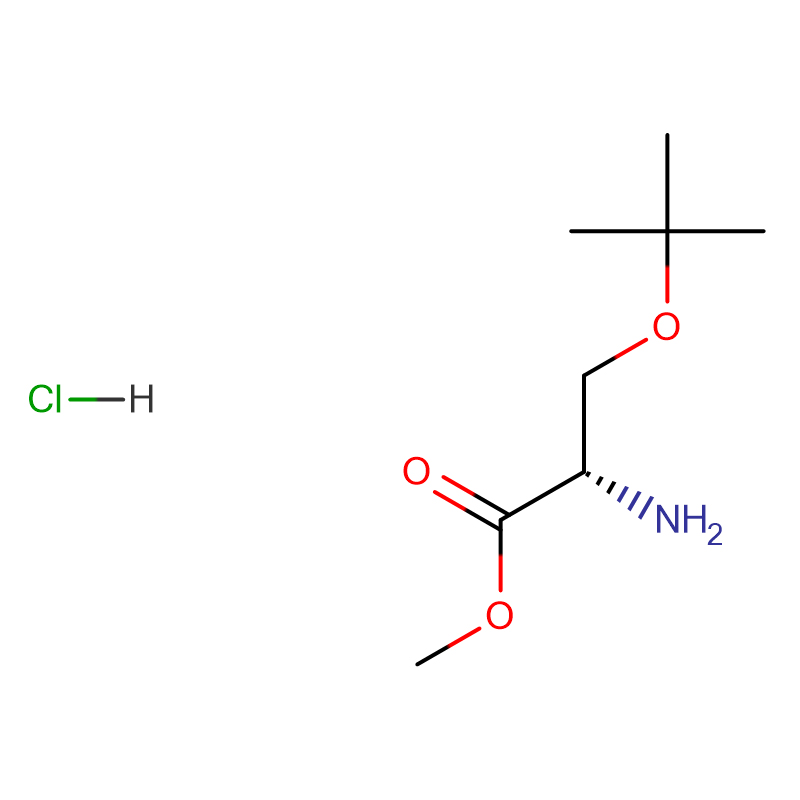

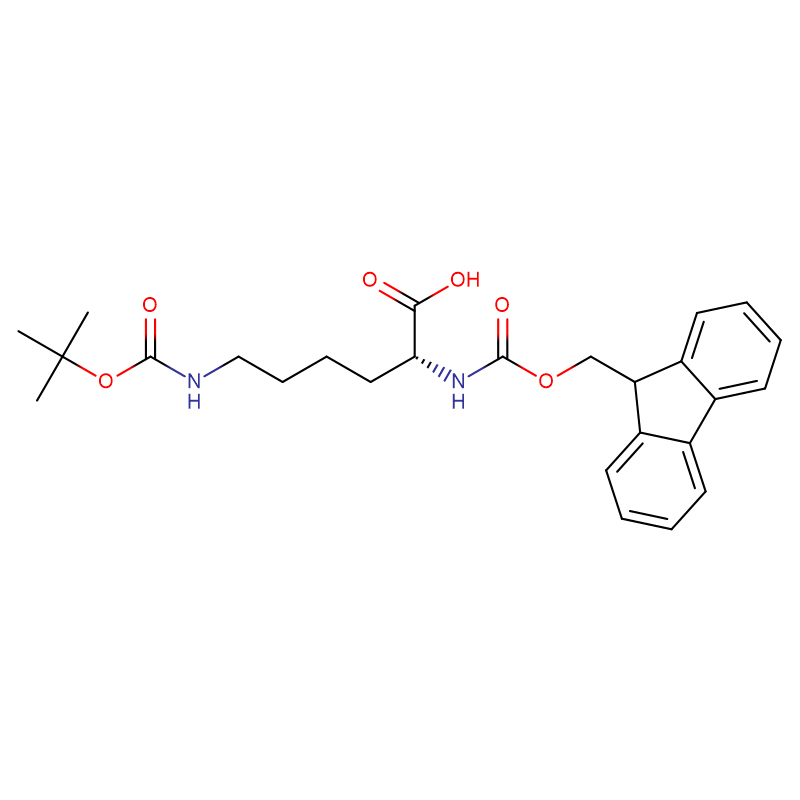

Understanding the metabolism of the microbial host is essential for the development and optimization of whole-cell based biocatalytic processes, as it dictates production efficiency. This is especially true for redox biocatalysis where metabolically active cells are employed because of the cofactor/cosubstrate regenerative capacity endogenous in the host. Recombinant Escherichia coli was used for overproducing proline-4-hydroxylase (P4H), a dioxygenase catalyzing the hydroxylation of free L-proline into trans-4-hydroxy-L-proline with a-ketoglutarate (a-KG) as cosubstrate. In this whole-cell biocatalyst, central carbon metabolism provides the required cosubstrate a-KG, coupling P4H biocatalytic performance directly to carbon metabolism and metabolic activity. By applying both experimental and computational biology tools, such as metabolic engineering and (13)C-metabolic flux analysis ((13)C-MFA), we investigated and quantitatively described the physiological, metabolic, and bioenergetic response of the whole-cell biocatalyst to the targeted bioconversion and identified possible metabolic bottlenecks for further rational pathway engineering.A proline degradation-deficient E. coli strain was constructed by deleting the putA gene encoding proline dehydrogenase. Whole-cell biotransformations with this mutant strain led not only to quantitative proline hydroxylation but also to a doubling of the specific trans-4-L-hydroxyproline (hyp) formation rate, compared to the wild type. Analysis of carbon flux through central metabolism of the mutant strain revealed that the increased a-KG demand for P4H activity did not enhance the a-KG generating flux, indicating a tightly regulated TCA cycle operation under the conditions studied. In the wild type strain, P4H synthesis and catalysis caused a reduction in biomass yield. Interestingly, the ΔputA strain additionally compensated the associated ATP and NADH loss by reducing maintenance energy demands at comparably low glucose uptake rates, instead of increasing the TCA activity.The putA knockout in recombinant E. coli BL21(DE3)(pLysS) was found to be promising for productive P4H catalysis not only in terms of biotransformation yield, but also regarding the rates for biotransformation and proline uptake and the yield of hyp on the energy source. The results indicate that, upon a putA knockout, the coupling of the TCA-cycle to proline hydroxylation via the cosubstrate a-KG becomes a key factor constraining and a target to further improve the efficiency of a-KG-dependent biotransformations.